What 15 Minute Habit Makes Any Resin 3D Printer Safer

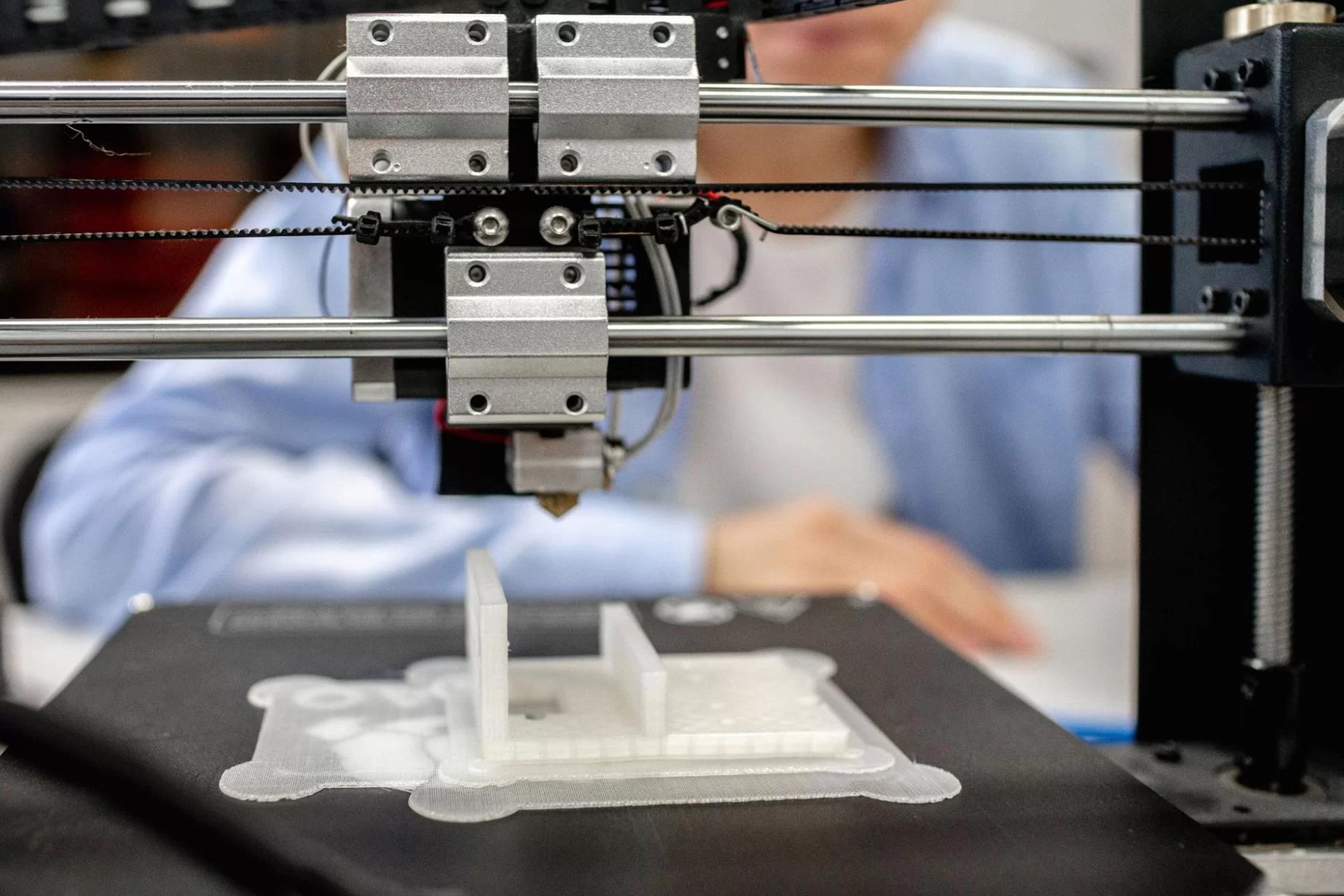

Resin printing unlocks a tier of resolution and surface finish that filament machines simply cannot replicate. However, the liquid photopolymers involved in this process introduce chemical hazards that demand serious respect. Many enthusiasts overlook safety protocols until they experience headaches or contact dermatitis.

Adopting a strict, fifteen-minute safety routine can drastically reduce your exposure to harmful substances. This habit ensures that your workspace remains a precision lab rather than a contamination zone. It focuses on containment, ventilation, and rigorous neutralization.

The Chemistry of Photopolymers

The core of stereolithography (SLA) and DLP printing involves curing liquid resin with UV light. This reaction releases Volatile Organic Compounds (VOCs) and ultrafine particles into the air. These byproducts are often odorless but can accumulate rapidly in small rooms.

Even if you operate a high-end resin 3d printer, the underlying chemistry remains hazardous. The uncured resin contains monomers and photo-initiators that are known skin irritants. Relying solely on the machine’s acrylic cover is a safety error, as it is not airtight.

When the cover is lifted, the concentration of these airborne chemicals spikes immediately. Without proper precautions, these compounds settle on surrounding furniture and carpets. Recognizing that the risk is airborne is the first step toward effective mitigation.

The 15-Minute Clean Cycle

Safety is not just about equipment; it is about procedural discipline. Searching for the best 3d printer is irrelevant if your post-processing workflow endangers your health. This routine must be executed every single time a print finishes.

This protocol minimizes the time uncured resin is exposed to open air. Do not rush this process; method is more important than speed.

- Pre-Ventilation: Turn on external exhaust fans five minutes before opening the machine.

- Gear Up: Don fresh nitrile gloves and a respirator rated for organic vapors.

- Containment: Move the build plate directly to a washing tray to catch drips.

- Sealing: Place paper towels and supports directly into a sealed trash bag.

- Wipe Down: Use Isopropyl Alcohol (IPA) to wipe the immediate work area.

Engineering Air Quality

Passive ventilation is rarely sufficient for resin workflows. Opening a window on the other side of the room does not effectively remove heavy vapors that tend to settle near the floor. You need an active system to manage the airspace effectively.

Negative Pressure Strategy

The most effective method is creating negative pressure. This involves an enclosure connected to an inline fan that vents air directly outside via a duct. This ensures that air flows into the printer area and out of the window, preventing fumes from leaking into your living space.

Carbon Filtration Limits

If venting outside is impossible, you must use a heavy-duty air purifier with a massive activated carbon filter. Small, USB-powered filters inside the printer are generally insufficient for scrubbing the volume of air in a standard room. They recirculate air rather than exchanging it.

The Reality of Health Risks

The danger of resin printing is rarely acute poisoning; it is chronic exposure. The goal of the 15-minute habit is to prevent long-term health issues that develop slowly over months or years of casual contact.

Chemical Sensitization

The most significant risk is sensitization. This is an immune response developed after repeated exposure to uncured resin. You might handle resin for months with no reaction, then suddenly develop a severe allergic rash. Once sensitized, you are likely allergic for life.

Proper Waste Management

Never pour used IPA or wash water down the drain. The dissolved resin is toxic to aquatic life. The correct method is to leave the dirty solvent in the sun. Once the resin cures into a solid sludge, filter the liquid and dispose of the solid plastic in the trash.

Conclusion

Resin 3D printing is a rewarding technology that requires a laboratory mindset. The hazards are manageable, but they cannot be ignored. By integrating this fifteen-minute cleaning and ventilation habit into your workflow, you protect your health and the safety of your household.

Treat every drop of uncured resin as a biohazard. This discipline allows you to focus on the creativity of the print, rather than the toxicity of the process. Sustainable printing is safe printing.

Disclaimer

The information provided in this article is for educational purposes only and is not a substitute for professional medical, safety, or legal advice. Resin 3D printing involves chemical hazards, and individual circumstances, workspace conditions, and health factors may vary. Always follow manufacturer guidelines, local regulations, and safety recommendations when handling photopolymer resins, isopropyl alcohol (IPA), or other chemicals. The author and publisher assume no responsibility for any injury, health issues, or property damage resulting from the use or misuse of resin 3D printers or the procedures described in this article. Users are responsible for implementing safety measures appropriate to their own environment and experience level.